Understanding and meeting key guidance and compliance when specifying healthcare fitted furniture is crucial for creating a safe environment.

Non-compliant furniture compromises quality. Budget constraints can result in cutting corners, risking compliance.

This blog summarises 6 key pieces of guidance you should know when specifying healthcare fitted furniture.

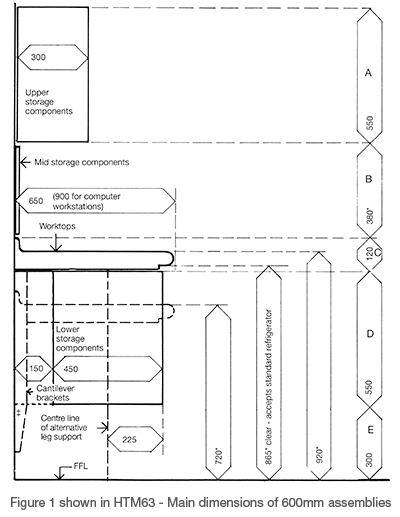

HTM63

Last updated in 2005, Health Technical Memoranda 63 has been archived as it is seen as ‘out of date’ with best practise evolving and progressing considerably since its publishing.

Providing guidance on storage, there are still sections of this document that are still applicable today, however.

For example, point 4.11 details that ‘Finished surfaces should be smooth and free from application marks.’

Smooth surfaces are easier to clean and can be done so more effectively, helping to prevent bacterial growth. Rough or textured surfaces can create microscopic crevices that can become bacteria reservoirs. This makes it almost impossible to clean and can lead to cross-contamination.

HTM71

Published by NHS Estates in 1988, HTM71 is a guide on the design, installation and operation of modular storage, trays and baskets. Like HTM63, it has been archived by the health authorities. However, it still provides a great deal of information but evolving practises must be taken into account.

HTM71 sets out requirements for modular trays and baskets such as sizes, how they are accessed and room and storage layouts that are required. With correct layouts and designs, HTM71 systems can significantly improve workflow efficiency and speed.

HBN 00-09

This health building note is arguably the most critical piece of guidance that is often overlooked in the design of healthcare fitted furniture. HBN 00-09 highlights major IPC issues and risks that need to be addressed at every stage of the project from the initial concept to ongoing maintenance in order to achieve ‘designed-in’ IPC.

It states that for HCAIs to be reduced, ‘it is imperative that IPC measures are “designed-in” at the very outset of the planning and design stages of a healthcare facility’. This highlights the necessity for healthcare fitted furniture providers to be involved in the design from the earliest stages of the project in order to deliver a project that has be the best possible IPC measures ‘designed-in’ from the start.

When designing a healthcare facility, there are a number of key design principles for facilitating cleanliness & cleaning as shown in 3.0:

| Principle | How to apply to FF&E design |

| Use finishes that are impervious, smooth and seamless, as far as practicable. | Solid surface worktops with coved upstands facilitate easy cleaning |

| Run hard flooring up the walls for a short distance to provide an easy-to-clean coving. | Coved vinyl flooring prevents water damage to cabinet plinths and allows easy cleaning of floors |

| Consider hands-free operation of utilities | Sensor taps removes a potential touch point for cross-contamination to occur. |

Section 3.0 also states “There may be pressure to choose the cheapest products/design. Attention to whole-life costs, including the costs of cleaning and maintenance, is important.”

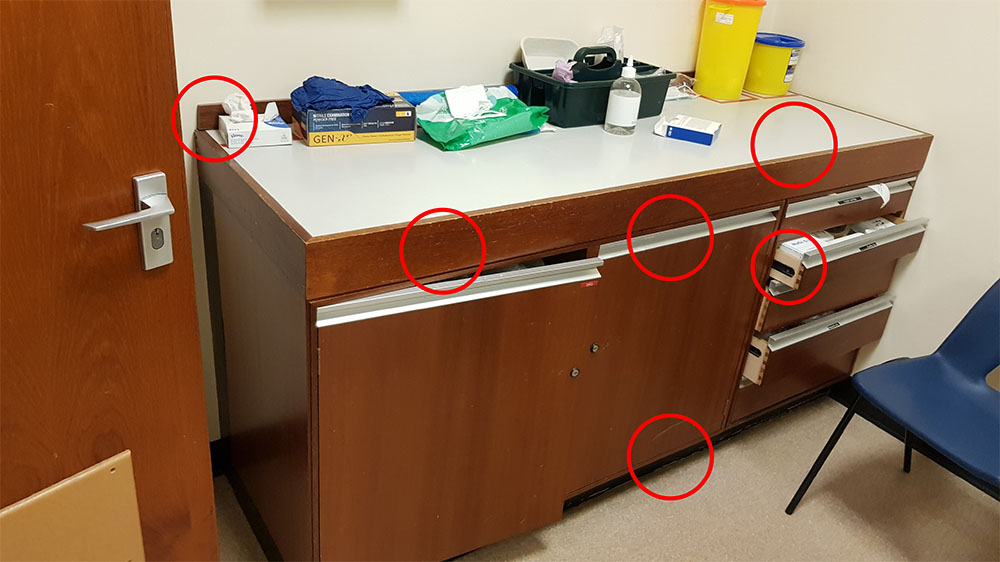

This point again highlights a common problem found across existing facilities where poor quality, non-compliant FF&E has been purchased resulting in damage and creation of infection hot spots.

When specifying healthcare fitted furniture, it is critical to consider the whole-life costs. Replacing or repairing damaged furniture systems can be significantly more costly than an initial upfront cost of robust, compliant systems.

3.108 explains the importance of choosing the correct quality of finishes. It is critical that materials are able to withstand the rigorous and regular cleaning regimes within healthcare facilities.

One common mistake made is MFC (melamine faced chipboard) worktops being specified in clinical areas. Easily damaged and impossible to clean, MFC worktops can be the perfect reservoir for bacterial growth. On the contrary, solid surface worktops are extremely durable and easily repaired. The smooth and seamless surface allows for easy cleaning and decontamination. To learn more about specifying healthcare work surfaces, Gerard Baxter takes you through 8 key steps to ensuring they are fully compliant.

HBN 00-01

This HBN is one of the key pieces of guidance for the design and construction of healthcare facilities. It addresses the government’s key priority of improving health outcomes for patients by emphasising the importance of design quality and the role of a fit-for-purpose healthcare facility.

Point 1.3 discusses the importance of how design quality can directly impact patient recovery and have a positive affect on staff performance and retention. This point is particularly relevant to healthcare fitted furniture; high quality furniture systems will result in greater efficiencies for staff, offering them a better experience and quality work environment.

5.24 “The need for sufficient secure storage should not be underestimated…space is often lost to other areas during the design process. This can have implications for both clinical practice and infection control.”

Point 5.24 highlights an issue that frequently arises in facility planning. Without sufficient storage, workspaces can become cluttered and disorganised. Not only does this hinder working practises for staff, it also poses an infection control risk and increases the likelihood of cross-contamination.

HBN 00-03

Health Building Note 00-03, titled ‘Clinical and clinical support spaces,’ offers design guidance and indicative room layouts for clinical support spaces within healthcare buildings.

The content within HBN 00-03 has been informed by evidence-based best practices, offering design solutions that are accessible, safe and fit-for-purpose.

It acknowledges the need for flexibility for individual project requirements by offering the indicative room layouts as exemplar design solutions rather than a set of guidelines that must be adhered to.

Although it is mostly relevant to new buildings, it is still applies to existing facility refurbs by recognizing the dynamic nature of projects and the importance of adaptable planning.

National IPC manual

The National Infection Prevention and Control Manual for England (NIPCM) is a guide developed to standardize infection prevention and control practices across healthcare settings.

The key aims of this document include:

- Standardization: Ensure a consistent UK-wide approach to IPC, whilst acknowledging potential operational and organizational differences across the country

- Best Practice: Establish the manual as best practice in non-NHS care settings

- Ease of Application: Facilitate easy implementation of effective IPC measures by staff.

- Skill Enhancement: Improve the application of knowledge and skills in IPC

- Risk Reduction: Help minimise HCAIs

Point 1.6 of the IPC manual goes over the safe management of the care environment. It details that the care environment must be:

- Visibly clean, free from non-essential items and equipment to facilitate effective cleaning. Healthcare fitted furniture should prioritize functionality and minimizing elements that could hinder cleaning practices. For example, surfaces that are hard to access such as sloping tops make cleaning difficult.

- Well maintained, in a good state of repair and with adequate ventilation for the clinical specialty. Robust construction and durable materials are paramount to ensuring the space can withstand the demands of these high traffic areas and frequent cleaning.

In Summary

By going beyond the standards discussed in this guide, Hygenius healthcare fitted furniture prioritises the safety and well-being of both patients and staff. Through listening and collaborating with clinicians and healthcare staff, our healthcare fitted furniture systems are designed to support front line professionals in their fight against infection and reduce HCAIs.

By delivering compliant interiors and buildings, we help the NHS and healthcare bodies ensure they create safer places for safer people.

Download our complaint standard room designs

Let our experience save you time. These typical healthcare room designs provide an indicative space layout incorporating our best practice from 50+ years of experience in infection control and patient safety. Explore exemplar rooms